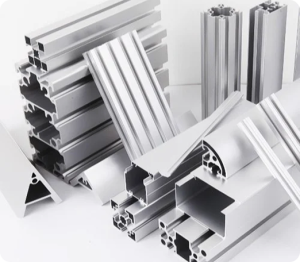

Aluminium Extrusion

Process, Applications, Materials & Industry Practices

What Is Aluminium Extrusion?

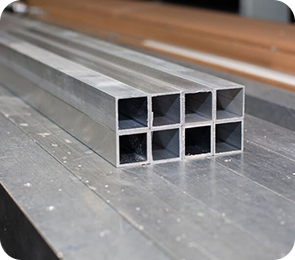

Aluminium extrusion is a manufacturing process in which a heated aluminium billet is forced through a hardened steel die to produce a continuous profile with a fixed cross-section. Once extruded, the profile is cooled, straightened, cut to length, and optionally heat-treated or surface-finished.

- Complex cross-sectional geometries

- High strength-to-weight ratios

- Consistent dimensional accuracy

- Efficient mass production

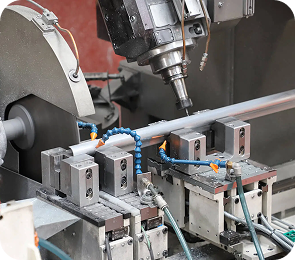

Aluminium Extrusion Process

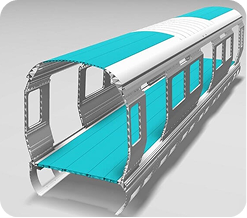

Aluminium extrusion is one of the most widely used metal forming processes in modern manufacturing. It allows aluminium to be shaped into complex, uniform cross-sections that combine structural strength, dimensional accuracy, and long-term durability. Because aluminium is lightweight, corrosion-resistant, and recyclable, extruded aluminium components are used extensively across construction, infrastructure, transportation, electrical systems, renewable energy, and industrial machinery.

Aluminium billets are cut to size and heated to extrusion temperature.

The billet is pushed through a die using hydraulic pressure.

Cooling

Profiles are air- or water-cooled immediately after extrusion

Stretching & Straightening

Removes internal stresses and ensures straightness.

Cutting

Profiles are cut to standard or custom lengths

Aging / Heat Treatment

The billet is pushed through a die using hydraulic pressure.

Anodizing, powder coating, or mill finish as required

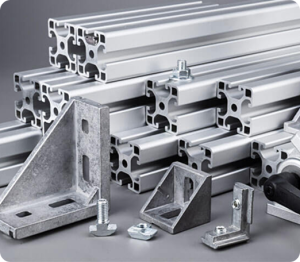

Applications of Aluminium Extrusions

Windows, doors, curtain wall systems

Solar panel mounting structures

Electrical enclosures and busbars

Industrial automation frames

Transport and logistics equipment

Windows, doors, curtain wall systems

Solar panel mounting structures

Electrical enclosures and busbars

Industrial automation frames

Quality Considerations in Aluminium Extrusion

High-quality aluminium extrusion depends on:

- Alloy consistency and billet sourcing

- Die design accuracy

- Temperature control during extrusion

- Straightness and tolerance inspection

- Surface finish uniformity

Common Aluminium Alloys Used in Extrusion

- 6063 – Architectural applications, decorative profiles

- 6061 – Structural and mechanical components

- 6082 – Heavy-duty industrial applications

Aluminium Extrusion Industry in India

India has developed into a reliable aluminium extrusion manufacturing hub due to:India has rapidly developed into a world-class and reliable aluminium extrusion manufacturing hub, a transformation fueled by a confluence of favorable economic, technological, and strategic factors. This ascendance is not accidental but a result of deliberate industrial growth.

The country’s aluminium production capacity stands at approximately 4.1 million tonnes annually, making it one of the largest producers globally. The extrusion industry, a critical downstream sector, leverages this massive domestic supply to achieve high-volume, quality production, cementing India’s reputation as a preferred manufacturing partner worldwide.

Modern extrusion facilities

Skilled technical workforce

Competitive production costs

Production Ecosystem

Growing export capabilities

About

Ratnashri

Ratnashri Aluminium is an ISO 9001:2015, ISO 14001:2015, and BIS certified manufacturer of aluminium extrusion products including solid and hollow profiles and sections, pipes, tubes, bars, rods, and billets. The company operates a modern manufacturing facility with imported machinery and in-house testing capabilities near Ahmedabad, supporting a wide range of industrial and architectural applications.